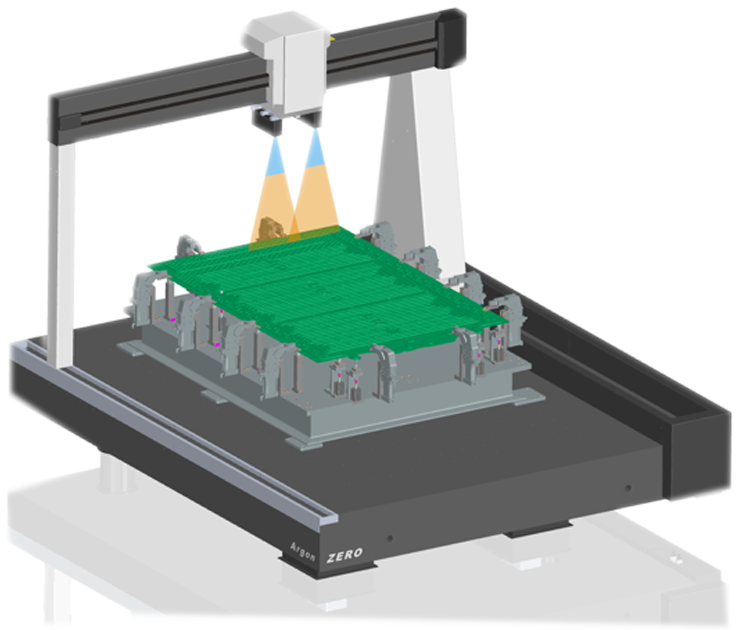

Aiming at the high precision requirements of battery box tray size inspection, many measurement features and high beat requirements, Suzhou Beishuo has developed a standard battery box tray size inspection station. The inspection station adopts 3D line scanning laser combined with high-precision motion platform to scan the parts at the same time, generate point cloud data, and realize high-speed calculation and analysis through data lightening, etc. to extract the measured features for dimensional analysis;

Non-contact line scan laser measurement;

Two 3D line scanning lasers combined with a high-precision motion platform scan the parts simultaneously, generate point cloud data, and realize high-speed calculation and analysis by means of data lightweighting, etc.; (the number of lasers is based on the number of beats)

Correlation accuracy with CMM (mm): 99% ≤ 0.1 for single direction of position, 99% ≤ 0.2 for surface contour;

Full-size detection speed: ≤ 100s (excluding loading and unloading), detection 90s + arithmetic 10s;

Suitable for battery box tray / water-cooled plate and other flat products size measurement