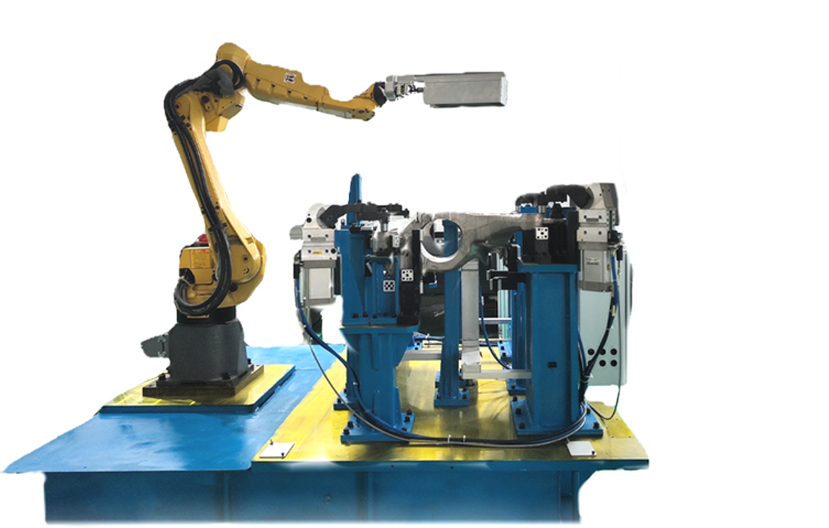

The Online Measurement System is a measurement system used on production lines to detect errors, omissions and dimensions of body-in-white parts and components. The system utilizes 3D laser sensors and graphic processing algorithms to identify and solve the coordinates of the features of the parts to be measured, so as to record and monitor the faults, omissions and dimensional status of the parts, and to improve the quality of the production line's parts delivery.

System features:

Rich data query: support single point query, regional query, overall query, statistical information query;

Convenient data statistics report: support all kinds of statistics report automatic export (CP/CPK);

Flexible alarm settings: including single-point size overrun alarm, multi-point correlation overrun alarm, size fluctuation warning and so on.

Precision industrial 3D camera: precision up to micron level, self-developed fusion imaging algorithm and reflective 3D reconstruction algorithm.

It can effectively deal with the interference of optical measurement caused by the complex structure of the workpiece, material diversity, visual blindness, alien reflections and other complex situations.

Based on self-developed database software, all measurement results are saved for each part; - Analysis report format (CSV, DMO, DFQ) can be customized according to customer requirements;

Software interface: all measurement results are connected and uploaded with the customer's MES system or data center for off-site viewing.